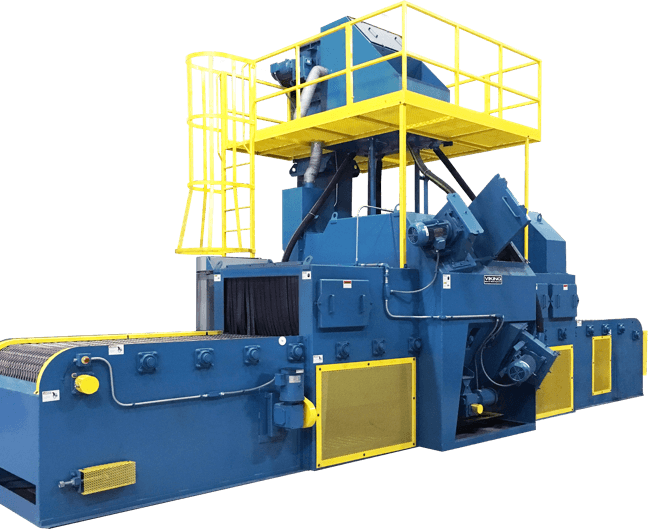

Combining quality workmanship with unparalleled customer service, Viking manufactures industrial shot blasting equipment and aqueous cleaning equipment customized to your parts-specific-needs.

Industries We Serve

Viking industrial shot blast and aqueous cleaning equipment can be found in numerous industries operating in more than 25 countries.

Industrial Cleaning Equipment

Machine Customization

At Viking, we do not simply match your part to the closest machine size that will work— our engineering team matches our cleaning equipment to your part.

Join Vikings Email Lists

By submitting this form, you are consenting to receive marketing emails from: Viking Wheel Blast Systems. You can revoke your consent to receive emails at any time by using the SafeUnsubscribe® link, found at the bottom of every email. Emails are serviced by Constant Contact

Discover the Viking Difference

-

All In-house Manufacturing

Viking Industrial Cleaning Equipment both in shot blast and aqueous cleaning equipment is manufactured and assembled completely in-house, which ensures optimum quality.

-

Built & Assembled in USA

Viking is completely owned and operated in the United States. Our location in the center of the country allows us to offer fast and convenient shipping.

-

Industry-Leading Warranties

We’re so confident in our industrial shot blast and aqueous cleaning equipment that we offer industry-leading warranties.

Speak with a Viking Expert

Contact Us